Online Custom Jewelry Design is pretty much all we do. We do have a few local customers, but the vast majority we will never meet in person. And we only know what someone looks like if they have a pic on their gmail avatar! While having custom jewelry custom made online has its own set of challenges, buying it in person has its own as well. And we have found that the value of making custom jewelry online far outweighs the benefits of having custom jewelry made in a brick and mortar store.

Designing a piece of custom jewelry can be an exciting process for an individual. Seeing their ideas come to life is very gratifying and the main reason why custom jewelry has become so popular. In this post, we will discuss Online Custom Jewelry Design, its pros and cons, the process, and tips to get exactly what you want for the best price.

How Custom Jewelry Is Made

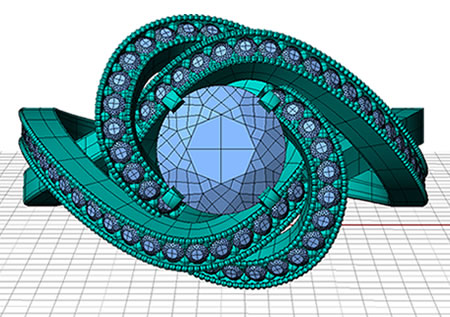

The first step is to hammer out what is going to be made. This includes the materials to be used, ring size, pendant size, etc. Once a price is agreed upon and a deposit paid, the piece will be created in a CAD program. When a draft is ready, it will be sent to the customers for review. They will then have the chance to make any changes they want made. Once the design has customer approval, the manufacturing process begins.

Wax

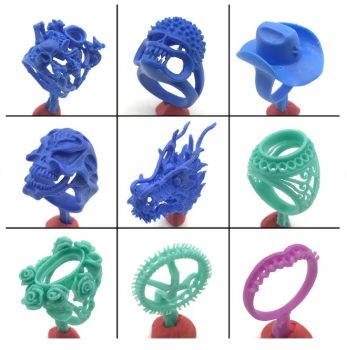

First, A CAD file is “grown” into a wax model through a process called 3D printing. In this process, the CAD file is first converted into a format that can be read by a 3D printer. The 3D printer then uses this file to create the wax model layer by layer. The printer deposits molten wax material onto a build platform, following the instructions from the CAD file. As each layer of wax is added, it solidifies and fuses with the previous layer, gradually building up the desired shape. Once the printing is complete, the wax model is carefully removed from the printer and can be used for investment casting.

Molding

Second, the mold is created by encasing the wax in a molten rubber. This melts away the wax, leaving a void in the shape of the wax. Next, the void is attached to a wax sprue, which is a wax rod used to create a channel for the molten metal to flow through during casting. The sprue is securely attached to the void using a heated tool. Finally, the mold is coated with a ceramic shell to create a mold. This shell is made by repeatedly dipping the pattern into a ceramic slurry and then coating it with a fine refractory material. Once the shell is dry and hardened, it is ready for the casting process.

Casting

First, the metal is prepared by melting it in a ceramic crucible using a torch, ensuring it reaches the desired temperature. Once melted, the molten metal is carefully is poured into the mold. It is allowed to cool and solidify before being removed it from the mold.

Finishing

After casting, the piece goes through a finishing process to achieve its final polished look. Firstly, the jewelry piece is carefully removed from the casting mold. Then, any excess metal or rough edges are filed down and smoothed out using various tools. Next, the jewelry is polished using abrasive materials such as sandpaper or polishing compounds to remove any remaining imperfections and create a smooth surface. Finally, the jewelry is cleaned and polished again to enhance its shine and luster.

These steps are the same when using buying custom jewelry online or buying it in person. The only difference comes when hammering out the design as Online Custom Jewelry Design solely utilizes email or phone calls. Buying it in person usually means at least 2 trips to the jeweler to hash out the design in person.

Why We Prefer Online Custom Jewelry Design

We think that when it comes to buying custom jewelry, opting for online shopping offers several advantages over visiting a physical store. Firstly, online stores provide a wider range of options, allowing customers to having something made just for them from the comfort of their own homes. Additionally, online retailers often offer better prices, making it more affordable to purchase customized jewelry. Lastly, the convenience of online shopping cannot be overlooked, as customers can easily compare prices, read reviews, and make purchases at any time that suits them. Unless you are buying a very expensive diamond and want to see it before it is put in your ring, there is no real need to actually go to the jewelry store. We find this time savings to be good for both parties.

Cons Of Online Custom Jewelry Design

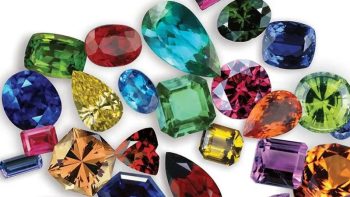

Online custom jewelry design offers convenience and a wide range of options for customers. However, there are is one drawback to consider. That is the reliance on online images and descriptions of stones isn’t optimal. It is always better to see stones in person if you are particular about them. Despite this drawback, online custom jewelry design should still be a viable option for those who prioritize convenience and variety.

How To Get The Best Prices When Having Custom Jewelry Made Online

When it comes to getting the best prices for custom jewelry made online, there are a few key strategies to keep in mind. First, it’s important to do your research and compare prices from different online jewelry makers. However, make sure you are comparing apples to apples. Make sure the details match exactly if you want to decide on price. Details such as diamond quality, gold purity, and weight all impact the price, so make sure they are equal.

Look for reputable websites that have a large portfolio of custom jewelry renderings. Look for things that are similar to what you want to make sure they possess the skill to design what you want. Read customer reviews to ensure their service, quality and reliability are up to snuff. Additionally, ask the person you talk to if the design work is done in house.

A large number of custom jewelers outsource the CAD design to design houses. You want to avoid this if possible as doesn’t provide the best and quickest results. We know as we used to do it. Think back to when you a kid and played telephone. What the customer wants can get lost in the transmission of the project to the designer. So, it is best to speak to actual person designing your custom jewelry. Using a design house can also cost more as you are adding another spoon to the pot.

Do You Have Unworn Or Scrap Jewelry?

Recycling unworn or scrap jewelry into new jewelry can save money in several ways. First, by repurposing old jewelry, you can avoid the cost of purchasing new materials. This can be particularly beneficial if you have valuable pieces that are no longer in style or no longer fit your taste. Instead of letting them sit unused in a drawer, you can have them transformed into something new and exciting, without the need to spend additional money.

Second, recycling jewelry can also save money by reducing the need for expensive repairs. Over time, jewelry can become worn or damaged, requiring professional repairs that can be costly. By repurposing old pieces, you can avoid these expenses and create something unique and personalized instead.

We Have Created Custom Jewelry Creations For Hundreds of Online Customers

We started out on etsy and custommade.com without a physical location. So all we did was Online Custom Jewelry Design for about 5 years. We have since opened an office, but still find dealing with the process via email or phone to be more efficient. So, if you are having reservations about having custom jewelry made online, you shouldn’t. We are confident that our expertise will overcome any distance barrier and our reviews support this.

So, check out out custom pendants or interguing ring and then contact us with your idea. You know what they say. Once you go custom, you nevver go back. To the mall.